Categories

New products

-

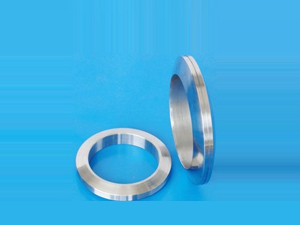

Lens Ring Joint Gasket

Ningbo Kaxite Sealing Materials Co., Ltd is one of the leading China Lens Ring Joint Gasket manufacturers and suppliers with one of the famous brands, as a professional company our factory is able to produce low price Lens Ring Joint Gasket with high quality. Welcome to buy discount and cheap products from us.

-

Double Jacket Gasket

Ningbo Kaxite Sealing Materials Co., Ltd is one of the leading China Double Jacket Gasket manufacturers and suppliers with one of the famous brands, as a professional company our factory is able to produce low price Double Jacket Gasket with high quality. Welcome to buy discount and cheap products from us.

-

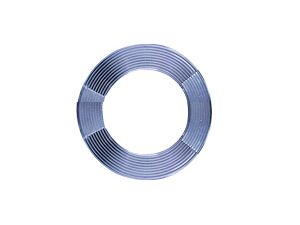

Corrugated Gaskets

Ningbo Kaxite Sealing Materials Co., Ltd is one of the leading China Corrugated Gaskets manufacturers and suppliers with one of the famous brands, as a professional company our factory is able to produce low price Corrugated Gaskets with high quality. Welcome to buy discount and cheap products from us.

-

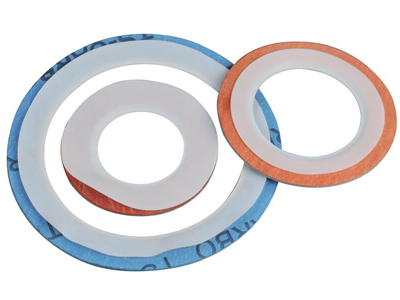

PTFE Envelope Gasket

Ningbo Kaxite Sealing Materials Co., Ltd is one of the leading China PTFE Envelope Gasket manufacturers and suppliers with one of the famous brands, as a professional company our factory is able to produce low price PTFE Envelope Gasket with high quality. Welcome to buy discount and cheap products from us.

-

Rubber Sheet

Ningbo Kaxite Sealing Materials Co., Ltd is one of the leading China Rubber Sheet manufacturers and suppliers with one of the famous brands, as a professional company our factory is able to produce low price Rubber Sheet with high quality. Welcome to buy discount and cheap products from us.

Solid material gaskets

HIT:8 DATE:2015-3-25

The idea behind solid material is to use metals which cannot be punched out of sheets but are still cheap to produce. These gaskets generally have a much higher level of quality control than sheet gaskets and generally can withstand much higher temperatures and pressures. The key downside is that a solid metal must be greatly compressed in order to become flush with the flange head and prevent leakage. The material choice is more difficult; because metals are primarily used, process contamination and oxidation are risks. An additional downside is that the metal used must be softer than the flange — in order to ensure that the flange does not warp and thereby prevent sealing with future gaskets. Even so, these gaskets have found a niche in industry.